The diversity of plastics and their properties can no longer be overlooked in this day and age if new products are to be manufactured cost-effectively and efficiently. The supposedly high costs of tool production alone prevent some developers from taking this path.

more

Plastics processing is the core of our company. On our modern injection moulding machines we process all technical thermoplastics according to your ideas and wishes. Our activities range from pure plastic injection moulding production, the encapsulation of metal parts, printing, assembly, gluing, ultrasonic welding to packaging and packaging.

moreBe faster and more efficient than your competitors

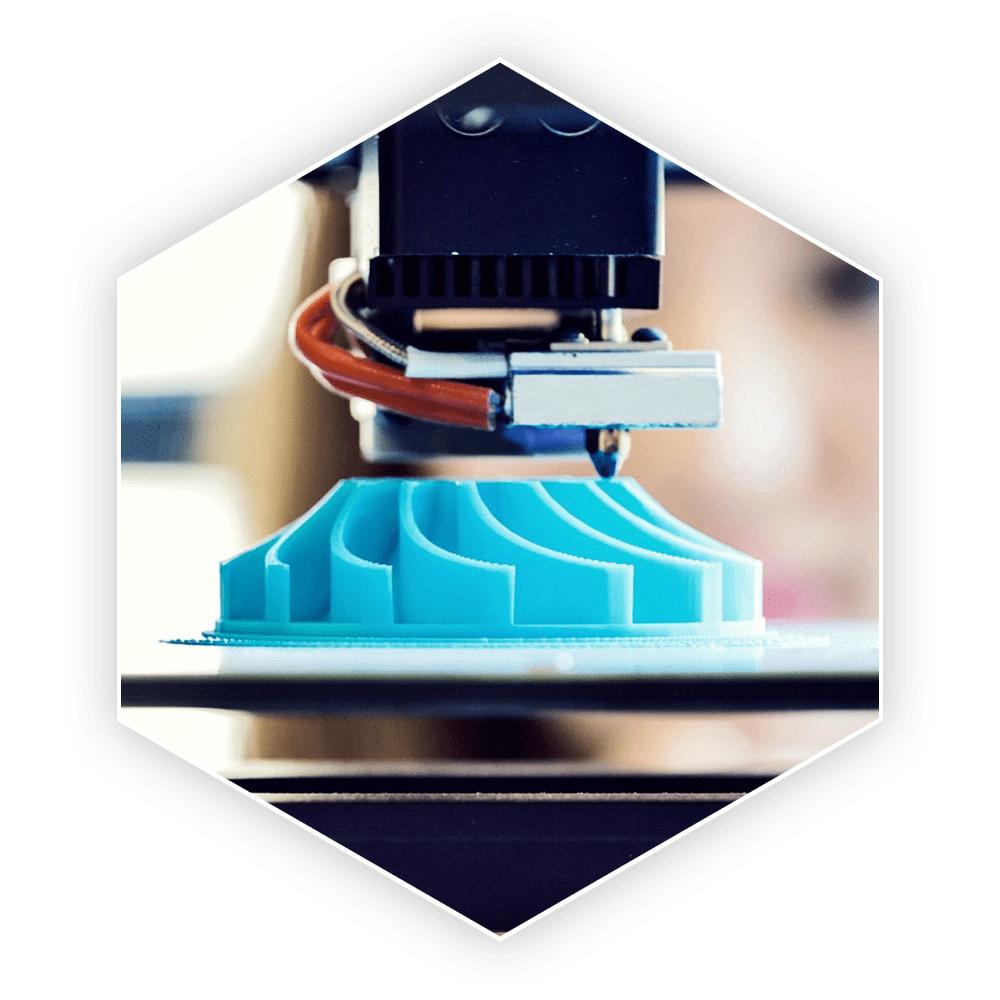

As a pioneer, we invested in rapid prototyping technology years ago in order to rule out any problems that might arise prior to tool design.

more

You don’t just need first-class components, but complete assemblies? Talk to us!

Both manual and automated methods are used to complete individual elements or entire assemblies.

moreDepending on the application and customer requirements, we use a variety of processes for material refinement.

We have internal facilities for pad printing, screen, hot stamping and multicolour printing, welding and laser marking.

more

Whether just-in-time, CPT or FCA. PECO offers its customers storage and shipping options that are always tailored to their product.

For the dispatch of your products we work with a wide variety of packaging and transport containers, both disposable and reusable.

more