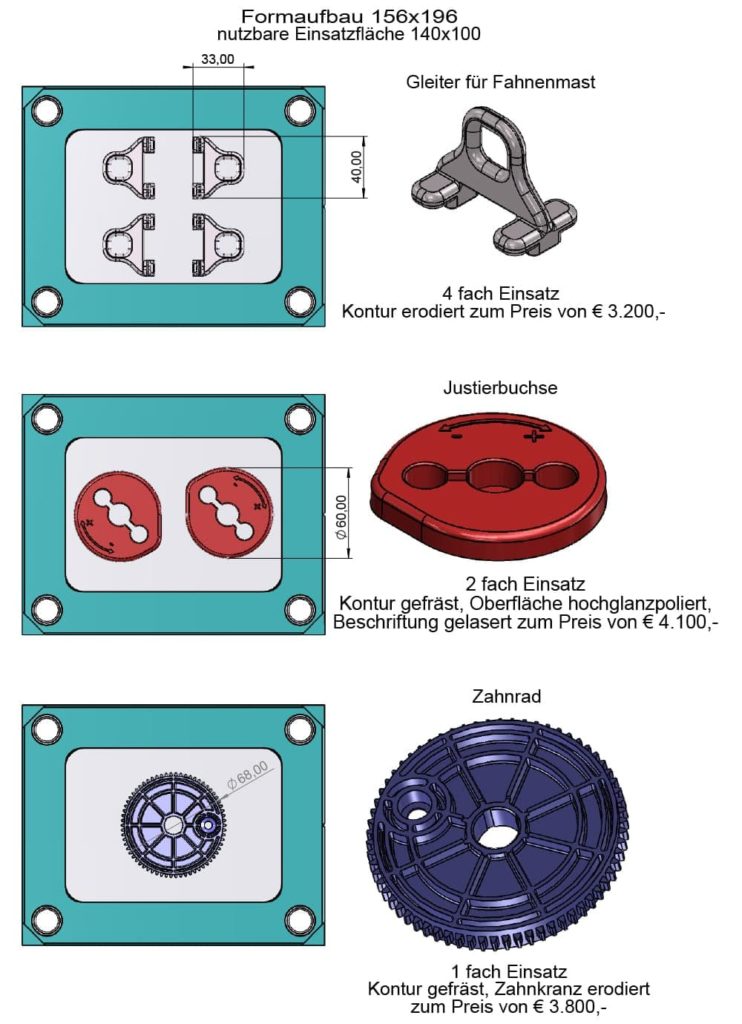

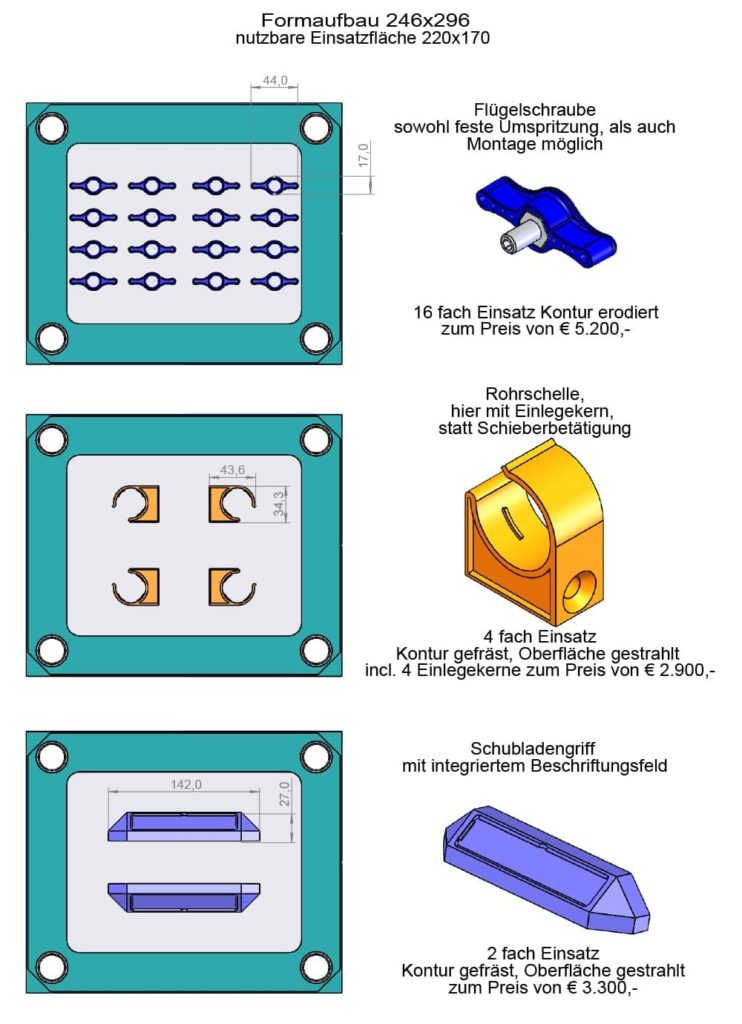

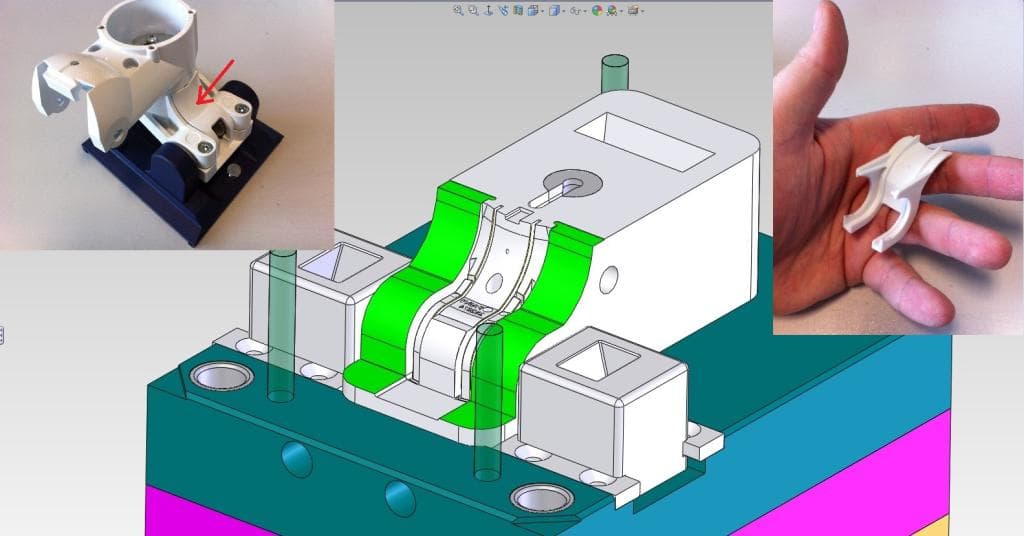

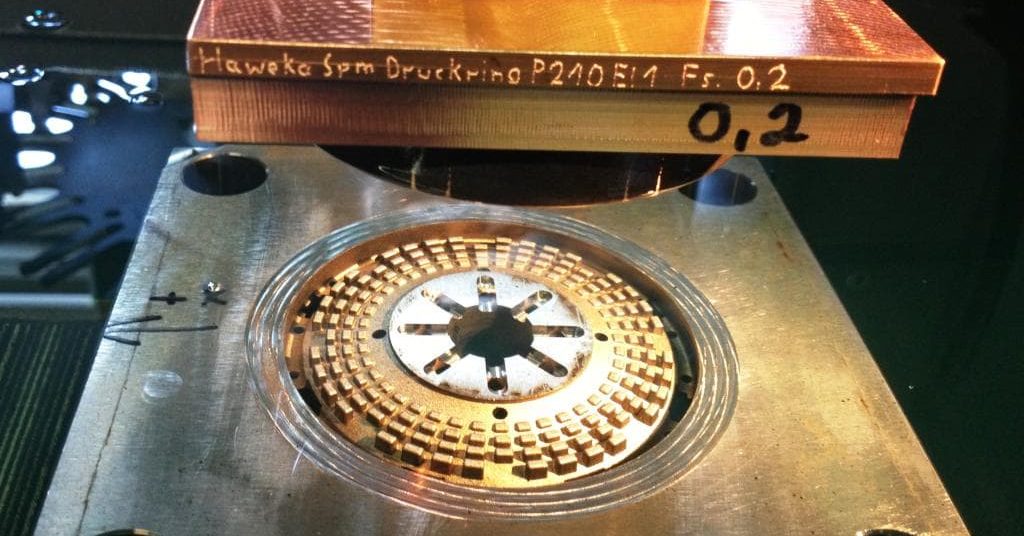

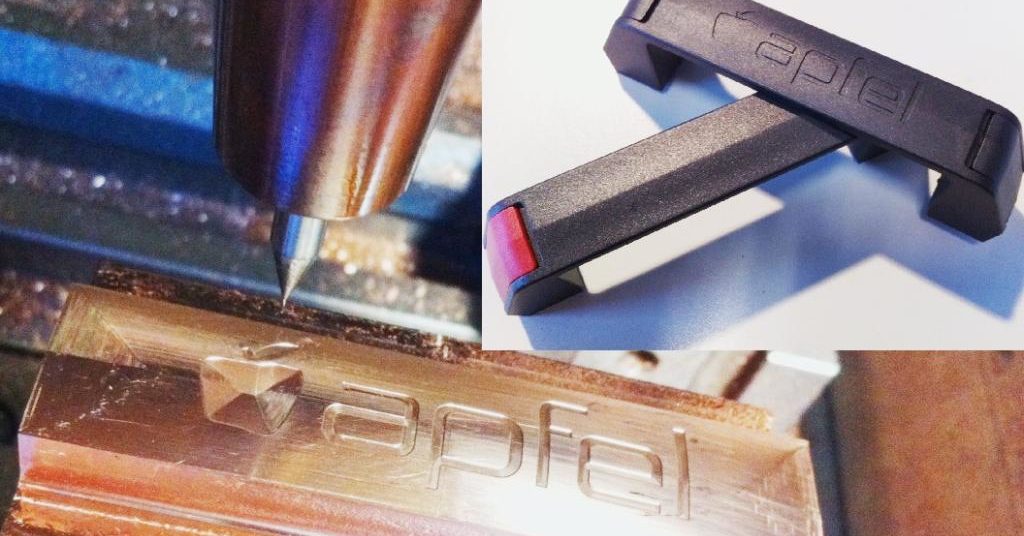

PECO has developed a new concept in which in-house master forms in various sizes are used. Customer-specific tool inserts are built into these master moulds, from which the injection moulded parts are produced in our injection moulding production. Since the log structures, including the peripherals, are Peco property, the potential customer only has to bear the costs of the contour insertion into the raw tool insert.

This results in savings of up to 70% compared to a conventional injection moulding tool!

Simple “open – close” moulds, even for quantities of less than 1,000 units per year, can thus be realised quickly and cheaply.

Here you can see some examples with the possible dimensions and the corresponding tool costs: